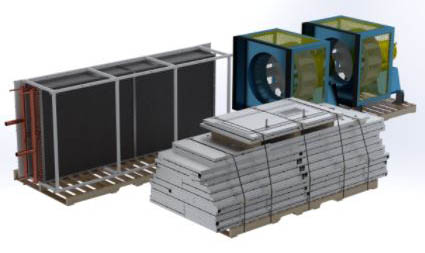

Our knock down field assembled air handling units are ideal for replacing existing air handlers. The precision of the design and the dimensional flexibility of these units make them the perfect solution for tight mechanical rooms. Our AHU site kits are specifically engineered to ensure all parts and pieces fit through the existing openings and that the weights comply with field constraints.

Our knock down field assembled air handling units are ideal for replacing existing air handlers. The precision of the design and the dimensional flexibility of these units make them the perfect solution for tight mechanical rooms. Our AHU site kits are specifically engineered to ensure all parts and pieces fit through the existing openings and that the weights comply with field constraints.

Ingénia Field Assembled AHU’s

Ingenia’s advanced assembly and pressure seal method, along with the use of pre-engineered bolted technology, provide a labor reduction of up to 60% over competing traditional field assembled units. Each of our field assembled air handling unit is engineered to meet the client’s expectations for :

- Superior air quality

- Long-term reliability

- 3-D modelling with clear assembly views

- Complete online project coordination

See the tabs below for product highlights. For more details see manufacturer’s catalog

- Features & Benefits

- Capacity & Performance

- Equipment & Design Options

- Quality Standards

- Certifications

Features & Benefits

- Infinitely variable cabinet dimensions, ideal flexibility to match existing unit dimensions

- Pre-configured unit sizes with ability to further modify cabinet dimensions

- Units can be all galvanized steel, aluminum, all stainless steel or a combination

- Highest energy efficient air handler with complete no-through metal construction

- Polyurethane foam injected panels with R-values ranging from 13 to 26

- Exterior and/or interior can be finished with an electrostatic powder coating

- Electrostatic antimicrobial powder coating for interior liners is available.

- Complete interior wash-down option with water containment floors, with drains available

- Can predict inlet, discharge and radiated acoustic performances with acoustic software

Capacity & Performance

- 1000 to 200,000 CFM units to meet our customers needs

- Casing acoustical performances are tested by an accredited independent laboratory

- Sound transmission values conform with ASTM designations E90-85 and E413-73

- Sound absorption values conform with ASTM standard: ASTM C423-84A and E795-90

- Cabinet pressure resistance is rated and tested up to positive and/or negative 15” w.g.

- Air leakage rate is tested to less than 0.5% at the rated cabinet pressure up to 15” w.g.

- Low noise NC-30 or NC-40 design

- Wall deflection less than 1/240 at the rated cabinet pressure

- Exceptional uniform wall thermal resistance, R-value = 6.5/inch thickness

- Cabinets meet and exceed the AHRI standard 1350

Equipment & Design Options

Cabinet

- Available wall thicknesses: 2”, 2.5”, 3” and 4”

- Polyurethane foam injected insulation

- Indoor and outdoor configuration available

Cooling

- Chilled water and direct expansion coils

- Direct and indirect evaporative cooling

- Non-mechanical economizer cycles

Fans & Motors

- Single or multiple EC fans

- DWDI or PLENUM SWSI fans

- AC, PM or EC motors

- Variable frequency drives or control packages for EC motors

Heating

- Hot water and steam coils

- Integral face and bypass coils

- Indirect and direct gas fired equipment

- Open and closed element electrical heaters

Energy Recovery

- Sensible or enthalpy energy recovery wheels

- Sensible and total heat recovery plate exchangers

- Refrigerant heat pipe systems

- Run around loop systems

Humidification

- Humidification options consist of steam, spray, media and evaporative

Dehumidification

- Passive dehumidification with the use of a desiccant wheel or active with desiccant wheels and regenerative heat source

Filtration

- Filter frames designed for high rigidity with easy-to-install bolted filter retainer clips

- All filter efficiencies including HEPA and bio-containment filtration

Sound Attenuation

- Media type silencer with DuPont™ Tedlar® lining

- Specially designed acoustical baffles to achieve ultra-low airborne sound performance

Electrical and Wiring

- Fluorescent or LED lights

- UV lights

- Power panels

- Electrical installation is done in the field by the electrical contractor

Quality Standards

- AFBMA 9 Load ratings and fatigue life for ball bearings

- AMCA 203 Field performance measurements

- AMCA 210 Laboratory methods of testing fans for rating purposes

- AMCA 300 Test code for sound rating air moving devices

- AMCA 500 Test methods for louvers, dampers and shutters

- ARI 410 Forced-circulation air cooling and air heating coils

- ASHRAE 62-89 ventilation for acceptable indoor air quality

- ASTM A525 Steel sheet, zinc coated by hot-dip process

- ASTM E90-09 Standard for measurement of airborne sound transmission loss

- NEMA MG1 National electrical manufacturers association (motors and generators)

- NFPA 70 National fire protection code

- NFPA 90A Installation of air conditioning and ventilation systems

- OSHA Occupational safety and health administration

- SMACNA HVAC metal duct association

- UL 1995 Heating and cooling equipment

Certifications

SEMCO Field Assembled AHUs

SEMCO offers field-assembled modular air handling units that recover energy while keeping people healthy, increasing ventilation, and controlling humidity. Field Assembled AHU’s have been proven in a broad range of applications to deliver the most cost-effective solution to the ASHRAE 62 requirement of providing continuous ventilation while controlling humidity under any operating condition.