Medical and Operating Rooms, Industrial and Food Process Dehumidifiers, Corrosion Prevention Dehumidifiers, Low and Ultralow Depoint Dehumidifiers

Desiccant dehumidifiers provide a highly effective solution for removing moisture from the air in low temperature and low humidity environments. Desiccant dehumidifiers use a desiccant material that attracts and absorbs water vapor, removing moisture from the air.

Desiccant dehumidification systems are commonly used for applications below 45% RH down to 1% RH. They are well suited for applications where there is a need to independently control the temperature of the space and the moisture level or humidity of the space.

Fisair Air Humidity Control Products

Level Solutions, a division of Koch Applied Solutions, LLC, partners with Fisair to offer a variety of air humidity control technologies. The Fisair lines include dehumidifiers for industrial materials and processes that require dry air, as well as low energy consumption evaporative coolers.

DF Air Dehumidifiers

Many industrial materials and processes require dry air. Of the many processes available for drying air, desiccant rotor technology has proven to provide the best combination of low installation cost, flexibility, and efficient operating costs. Fisair supplies a range of desiccant dehumidifier series adapted to specific applications.

- Dehumidifiers DFRM

- DFLEX

- DFLOW

- DFRA

- DFRB

- DFRC

- DFRD

- DFRIGO

Dehumidifiers DFRM

- A wide range of configurations

- Highly reliable equipment

- Drying capacities from 10 to 100 lbs/hr

- Dry air flow rates from 250 to 3500 CFM

DFLEX

- Flexible modular range

- Adaptable to specific solutions

- Highly reliable equipment

- Drying capacities from 100 to 350 lbs/hr

- Dry air flow rates from 4500 to 15,000 CFM

DFLOW

- Excellent low dew point performance

- Low energy consumption

DFRA

- A wide range of configurations

- Highly reliable units

- Drying capacities from 10 to 100 lbs/hr

- Dry air flows from 250 to 3500 CFM

DFRB

- Made from stainless steel

- Highly compact, robust and portable dehumidifiers

- High reliability and low energy consumption

DFRC

- Mobile and heavy duty drying

- Series aimed at temporary drying

- Robust chassis and finish to protect against corrosion

- Ideal for surface treatment and rental applications

DFRD

- Features additional fan to increase the drying capacity and wet air pressure

DFRIGO

- Ice-free with no energy loss

- Units designed to reduce humidity in refrigerated areas and processes

- Thermal insulation, robust design and energy efficiency

HEF Evaporative Coolers

Dry air has a huge natural capacity for cooling by exchanging heat for water. These evaporative coolers are based on a low energy consumption operating principle.

- AtomSpray Water Atomisation Equipment

- Coolers HEF2E

- Evaporative Air Cooler HEF3-CAD

- Evaporative Cooler HEF7

AtomSpray Water Atomisation Equipment

- Adiabatic humidification and cooling systems

- AtomSpray water atomisation that uses compressed air as the fluid to drive water

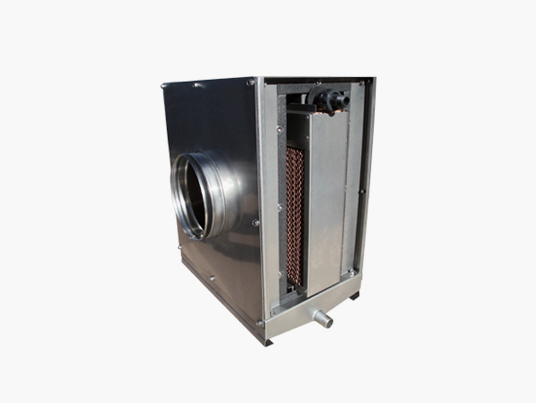

Coolers HEF2E

- Most hygienic and efficient

- Contact panel evaporative humidifiers

- Best performance & efficiency at lower pressure drop and certified hygiene

Evaporative Air Cooler HEF3-CAD

- Low height solution

- Hygienic range for reduced heights

Evaporative Cooler HEF7

- Hygienic and efficient

- Contact panel evaporative humidifiers

- Low pressure drop efficiency and certified hygiene

- Contact panel evaporative humidifiers

SEMCO Desiccant Systems

Level Solutions, a division of Koch Applied Solutions, LLC, is proud to partner with SEMCO for quality desiccant systems. SEMCO offers desiccant-based products and systems to recover energy, increase ventilation and control humidity. SEMCO products are designed not only to provide cost-effective energy efficiency, but also overall comfort.

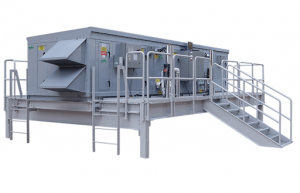

Ascendant Series - ADM/EP-ADM

This series is a conventional cooling, active desiccant hybrid system, optimized to deliver low dew points (down to 20°F) while minimizing tons of cooling input. The Ascendant Series delivers the best indoor air quality and performance, while maximizing energy efficiency. It is ideal for applications requiring low dew point temperatures and supply air humidity levels as low as 15 grains, including:

- hospital operating rooms

- archival and dry storage

- hotel/condo buildings

Operating without the need for exhaust heat recovery, it is well-suited for applications that require 100 percent outdoor air when exhaust air cannot be collected.

The Ascendant Series is engineered to allow ideal space temperature and humidity control to optimize indoor air quality, comfort, and safety. Additionally, it provides performance that helps building systems surpass ASHRAE 90.1 building energy, ASHRAE 170 ventilation, and ASHRAE 62.1 indoor air quality (IAQ) standards.

- Specifications

- Features

- Applications

- Literature

Specifications

- Air Flow Range: 1,000 – 40,000 CFM

- Dew Point: 18 – 45

- Grains of Moisture: 14 – 46

- Humidity Control: 25% – 48%

Performance specifications help building systems surpass ASHRAE 90.1 building energy, ASHRAE 170 ventilation, and ASHRAE 62.1 indoor air quality (IAQ) standards. Created to allow ideal space temperature and humidity control, the Ascendant Series enhances indoor air quality, comfort, and safety.

Features

The Ascendant Series offers 25% to 50% lower energy costs than conventional refrigeration-based dehumidification systems, delivering the best indoor air quality and performance, while maximizing energy efficiency.

Applications

Ideal applications include: hospital operating rooms, archival and dry storage, hotel/condo buildings, and other applications requiring low dew point temperatures and supply air humidity levels as low as 15 grains. This series operates without the need for exhaust heat recovery, making it ideal for applications requiring 100-percent outdoor air when exhaust air is unavailable for collection.